U Tube Heat Exchanger

A U-tube heat exchanger is a type of shell and tube heat exchanger commonly used in industrial applications such as chemical and petrochemical processes. It is known for its ability to handle thermal expansion effectively, making it ideal for systems where large temperature differences exist between the two fluids involved.

Table of contents

- U Tube Heat Exchanger Specification

- U Type Heat Exchanger Function

- U Tube Bundle Heat Exchanger Features

- U Tube Heat Exchanger Design

- U Tube Type Heat Exchanger Diagram

- U Tube VS Straight Tube Heat Exchanger

- Difference Between Floating Head and U Tube Heat Exchanger

- U Tube Condenser Applications

- U Tube Shell and Tube Benefits

- U Tube Exchanger Advantages

- Disadvantages of U-Tube Heat Exchanger

- U Tube Heat Exchanger Calculation

- Cross Over Temperature of U Tube Shell and Tube

U Tube Heat Exchanger Specification

| U Tube Heat Exchanger Size |

|

|---|---|

| Manufacturing Type |

|

| Major Parts |

|

| Dimensions Standard |

|

| Manufacturing Method |

|

| Material |

|

| Certificates |

|

| Origin |

|

| Application |

|

| Surface Treatments |

|

| Short Radius Elbow Standard |

|

| Finish |

|

| Value Added Services |

|

Explore the features and functions of U-tube condensers

U Type Heat Exchanger Function

The U-tube heat exchanger operates by allowing one fluid to flow through the tubes while the other circulates around them. This design is particularly effective in environments with high temperatures and pressures, offering reliable heat transfer performance.

U Tube Bundle Heat Exchanger Features

- Excellent heat transfer efficiency

- Fixed at both ends, ensuring unidirectional flow

- Easy to maintain and clean

- Capable of handling high pressure and temperature

U-tube bundle heat exchangers provide efficient heat transfer with a compact design

Designed to maximize heat transfer while minimizing energy consumption and operational costs, these exchangers are known for their strong pressure resistance and superior thermal performance. This makes them an excellent choice for industrial applications requiring reliable and efficient heat exchange.

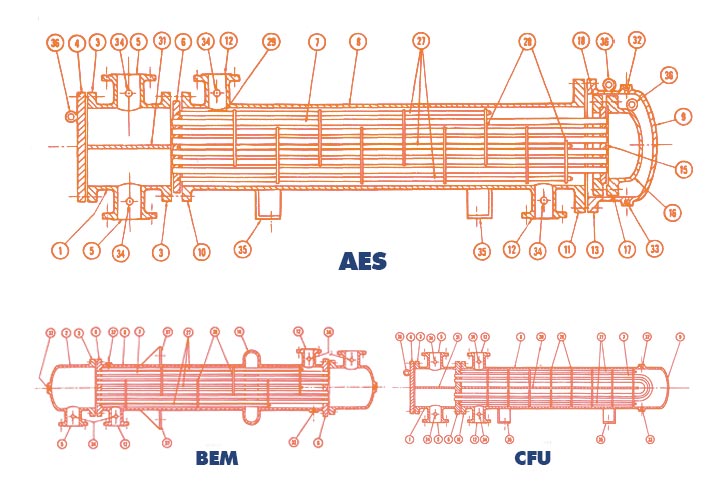

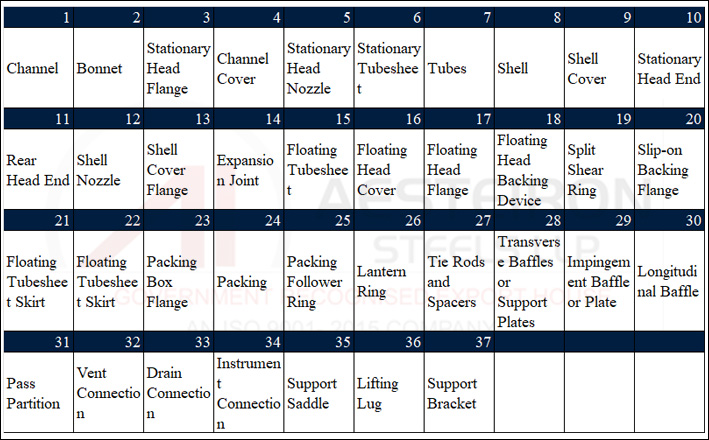

U Tube Heat Exchanger Design

Understand the components and working principle of a U-tube shell and tube heat exchanger

The working principle of a U-tube shell and tube heat exchanger relies on the arrangement of tubes within a shell to facilitate heat transfer. The following diagram provides a detailed view of its structure and how it functions.

U Tube Type Heat Exchanger Diagram

U Tube VS Straight Tube Heat Exchanger

| Feature | U-Tube | Straight |

|---|---|---|

| Construction | Compact and robust | Simpler |

| Design | Fixed at both ends | Bundled in a shell |

| Cost | Higher | Lower |

| Thermal Expansion | More | Less |

| Heat Transfer Area | Good | Better |

| Maintenance | More complex | Easier |

| Space Requirements | Compact | Bulkier |

| Lifespan | Longer | Varies |

Difference Between Floating Head and U Tube Heat Exchanger

| Feature | Floating Head Heat Exchanger | U-Tube Heat Exchanger |

|---|---|---|

| Design | One end is fixed, the other is floating | Fixed at both ends |

| Maintenance | Easier | More challenging |

| Heat Transfer Area | Larger | Efficient |

| Space Requirements | Bulkier | Compact |

| Cost | Higher | Lower |

| Lifespan | Longer | Robust |

U-type heat exchangers are widely used in petroleum and chemical industries

Heat exchangers are essential in transferring heat between two distinct channels, either directly or through a barrier. In the petroleum and chemical sectors, U-type heat exchangers are preferred due to their compact structure, high heat output, and ability to withstand high pressure. This makes them a reliable solution that minimizes risks of pressure failure and ensures strength under harsh conditions.

U Tube Condenser Applications

- Pressure Vessels

- High Pressure Equipment

- Cryogenic Pressure Vessels

- Boilers

- Air Cooler Tubes

- Tube Sheets of Heat Exchangers

- Refineries

- Air Pre Heaters

- Fertilizer Plants

- Chemical Factories

- HVAC Systems

U Tube Shell and Tube Benefits

- High Efficiency

- Enhanced Heat Transfer

- Compact Design

- Less Maintenance

- Versatility

- Excellent Durability

- Cost Effectiveness

- Easy to Install

Discover the advantages and disadvantages of U-tube heat exchangers

U Tube Exchanger Advantages

- Recyclable

- Energy-efficient

- Wide range of designs

- Cost-effective

- Available in various materials

- Space-saving designs

- Good thermal compensation

- Easy maintenance

- Can handle different flow rates, fluids, and temperatures

Disadvantages of U-Tube Heat Exchanger

- Limited suitability for extreme temperature differences

- Potential warping due to thermal stress

- Requires more space

- Needs regular cleaning

- Complex internal structure

- Prone to internal leakage

U Tube Heat Exchanger Calculation

Cross Over Temperature of U Tube Shell and Tube

| Temperature | Water | Oil |

|---|---|---|

| Outlet | 51.5 | 50 |

| Inlet | 30 | 80 |

| Flow Rate | 15 L/min | 25 L/min |

Stainless Steel Raw Materials 316

Nice Fashion Kitchenare Stainless Material,Safe Healthy Metal Titanium Foil,Stainless Steel Strip Healthy Food Grade,Stainless Titanium Strip For Elevator

Ningbo Boss Metal Material Co., Ltd. , https://www.boss-metal.com