Voice of the Customer:Â Empowering Medical Device Innovation Through Precision Manufacturing

Trice Medical: Leading the Way in Minimally Invasive Care

Trice Medical is dedicated to creating minimally invasive solutions that make healthcare more accessible and affordable. Their products, such as the Tenex ultrasonic surgical aspirator and disposable arthroscopes, are designed to be used in lower-cost settings like ambulatory surgical centers (ASCs) and physician offices. This approach helps reduce the burden on hospitals and improves patient access to advanced care.The Role of AIM Processing in Trice Medical’s Success

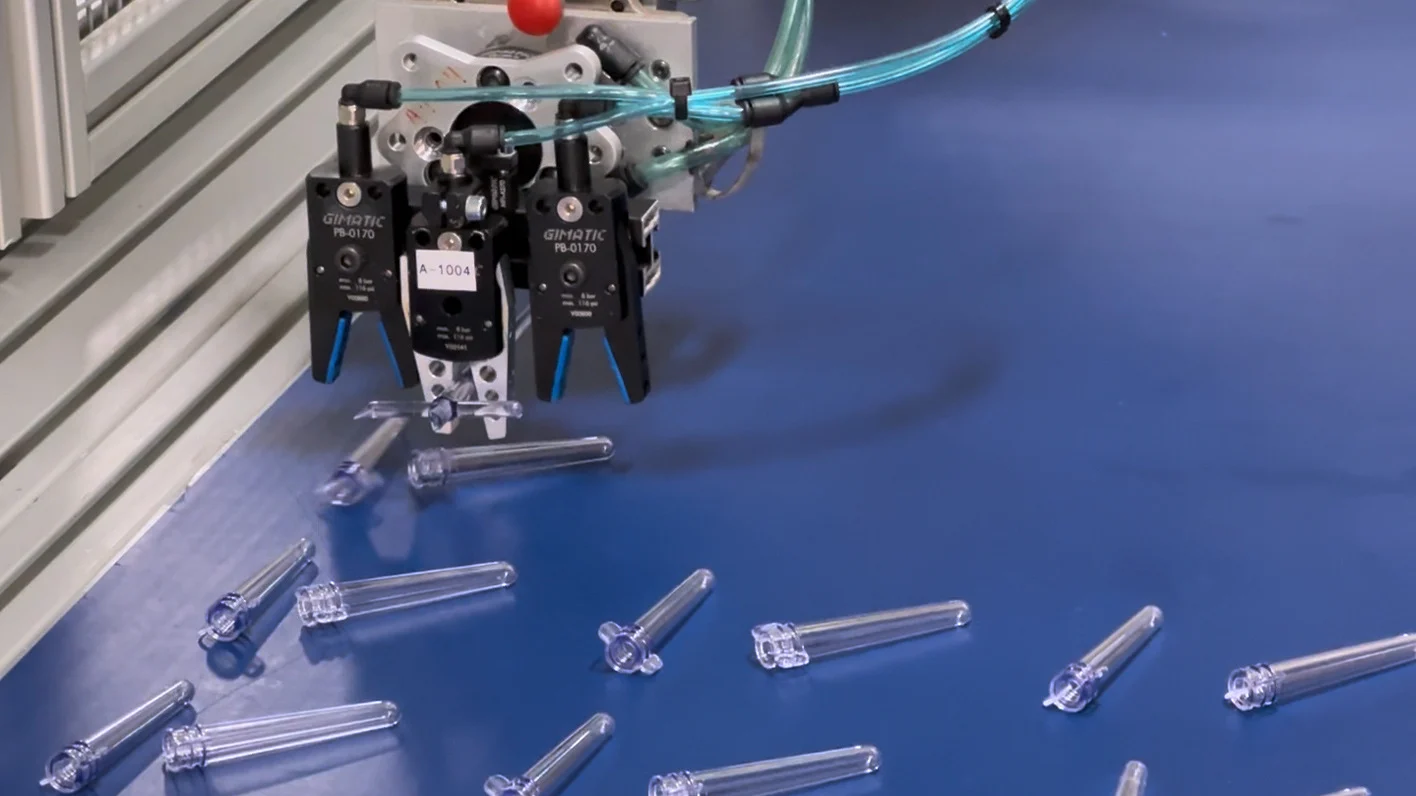

AIM Processing plays a crucial role in the production of Trice Medical’s Technics line of disposable ultrasonic surgical aspirators. Beyond just supplying parts, AIM brings expertise in process optimization and quality control. Their commitment to excellence ensures that every component meets the highest standards, allowing Trice Medical to deliver consistent, reliable products to the market.Why Trice Medical Chose AIM Processing

For a small startup like Trice Medical, navigating the complexities of injection molding can be overwhelming. When they struggled with inconsistent quality and lack of support from previous suppliers, AIM Processing stood out. Mike emphasized that what made the difference was the personalized attention and hands-on support provided by AIM. "We weren’t getting the time or attention we needed from larger companies. AIM’s personal touch made all the difference," he said.Overcoming Manufacturing Challenges Together

Before partnering with AIM, Trice Medical encountered numerous issues, including non-conformance and unreliable parts. AIM quickly stepped in, helping refine processes and implement better controls. As a result, product reliability improved dramatically. "AIM brought in the expertise to identify critical parameters and help us control the process better," Mike noted.Key Challenges Addressed:

- Inconsistent component quality

- Non-conformance issues

- Lack of in-house injection molding expertise

Smooth Tooling Transfer: A Test of Partnership

One of the most important milestones in the Trice-AIM relationship was the tooling transfer from a previous supplier. Despite the risks involved, the transition was seamless, thanks to AIM’s proactive approach. "Tooling transfers can be tricky, but AIM made sure everything went smoothly without any problems," Mike said.

A Decade of Trust and Growth

Since 2014–2016, Trice Medical has worked closely with AIM Processing, building a strong, long-term relationship. Over the years, the focus has shifted toward quality assurance, with AIM’s team playing a vital role in ensuring compliance and consistency. "Their quality team has been a huge asset to our business," Mike added.Onshoring: A Strategic Advantage

In an industry increasingly reliant on offshore manufacturing, AIM’s domestic presence is a major advantage. With stricter regulatory requirements in recent years, having a U.S.-based partner has been crucial for Trice Medical. "Many companies should look at domestic partners like AIM. They offer reliability, compliance, and peace of mind that you won't find elsewhere."Focus on Innovation and Patient Care

Thanks to the strong partnership with AIM, Trice Medical can concentrate on what matters most: innovation and patient outcomes. Mike explained that having a trusted manufacturing partner allows them to avoid distractions and focus on clinical needs. "Our goal is to deliver safe, effective devices that make a real difference for patients. AIM's support has allowed us to do just that."Key Benefits of the Partnership:

- Reliable and consistent part quality

- Proactive communication and updates

- Reduced failure rates and yield loss

- Expert engineering support

- Domestic manufacturing for supply chain stability

Building a Stronger Future Together

The Trice Medical and AIM Processing partnership has proven to be a powerful example of how the right supplier relationship can drive success. With fewer manufacturing issues and greater focus on innovation, Trice Medical continues to grow and meet the evolving needs of the healthcare industry. If you're interested in learning more about this successful collaboration, check out our exclusive video interview with Mike Steen, where he shares more insights into how AIM Processing has contributed to Trice Medical's achievements.Â

Titanium Disc,Medical Titanium Disc,Pure Medical Titanium Disc,Medical Grade Titanium Disc

TMT INDUSTRY , https://www.tmtmedtech.com