A gripper is a key component in automation systems, often used as an end effector on robotic arms or cartesian robots. Its main function is to grasp and move parts from one location to another. However, the process is more complex than just closing the jaws. Proper grip techniques are essential to avoid damaging delicate items.

In this post, we will explore how to use a gripper effectively to handle sensitive loads without causing damage.

| CHALLENGE |

Grip a delicate part without damaging it

|

Â

![Gripping a delicate load]()

Consider a test tube holding virus samples. It requires a gentle touch during handling. The gripper must adjust its force and speed automatically to prevent any impact or excessive pressure. This principle applies not only to test tubes but also to various other fragile objects.

| SOLUTION |

EH Series gripper system with stored push motion and speed data settings

|

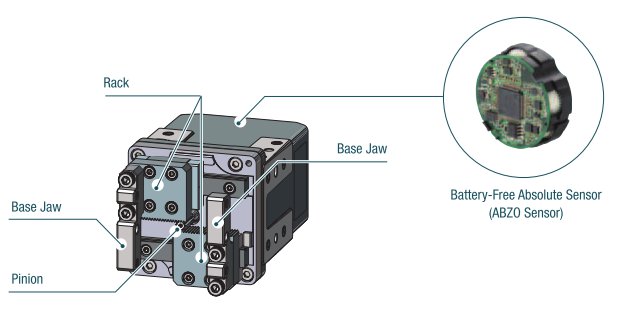

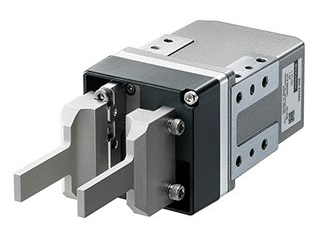

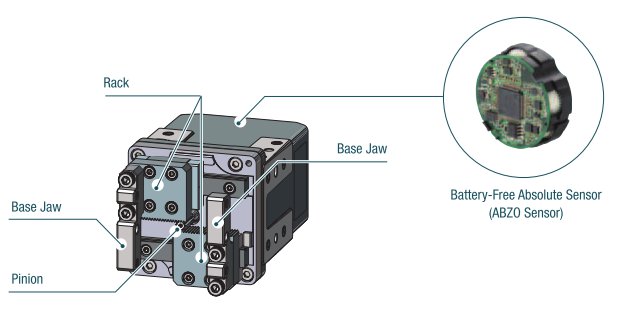

The EH Series gripper features a dual rack and pinion design with two base jaws. As the motor rotates the pinion, both jaws extend or retract simultaneously with high precision of +/-0.02 mm. This allows for flexible configurations with different pincers tailored to specific applications.

Various driver options are available, including Pulse Input, RS-485, EtherCAT, and EtherNet/IP. These provide flexibility depending on your control system requirements.

The EH Series also includes an absolute encoder (ABZO Sensor), eliminating the need for external sensors and batteries. This helps reduce space requirements while ensuring reliable operation.

For example, using a Stored Data (RS-485) driver, you can store up to 256 motion profiles. These include position, speed, and push motion settings. Once programmed with MEXE02 software, these profiles can be triggered via BCD inputs, either physically or over a network.

|

What Is Push Motion?

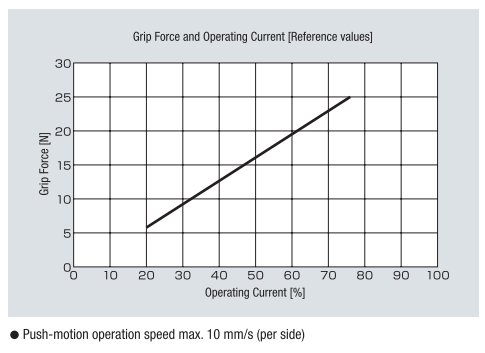

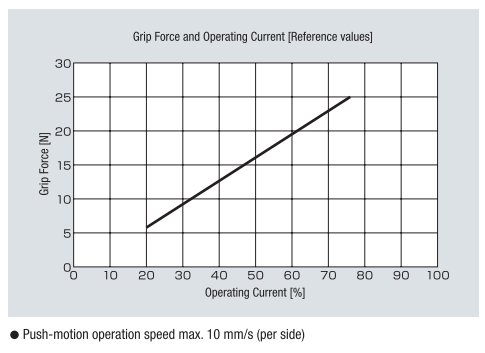

Push motion limits the torque of a stepper motor by controlling its current. By adjusting the current in 1% increments, you can precisely control the grip force. This is crucial when handling delicate items like test tubes.

|

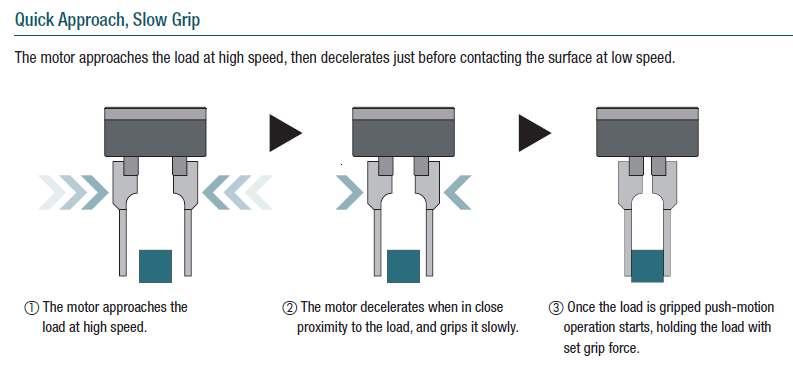

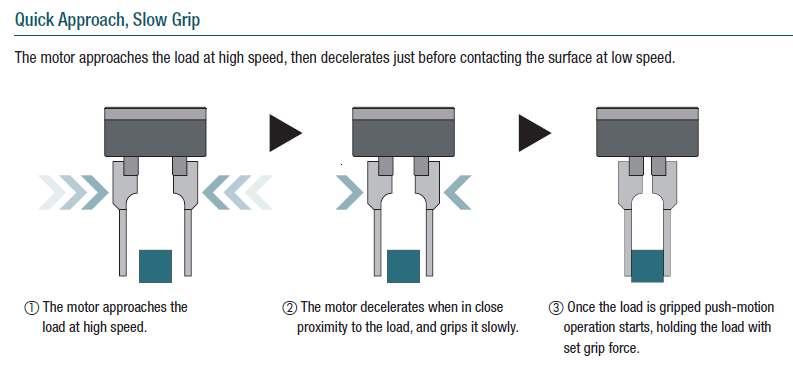

To properly grip a load, use push motion combined with variable speeds. This ensures that the gripper approaches the object at high speed, slows down near the load, and grips gently. Once the desired grip force is achieved, the gripper holds it steady until the item is released.

| Key Point |

Use push motion with multiple speed settings to minimize impact force and impact

|

With the linked motion sequence function, you can create continuous motion profiles with varying push motion forces and speeds. This allows for smooth and controlled gripping operations.

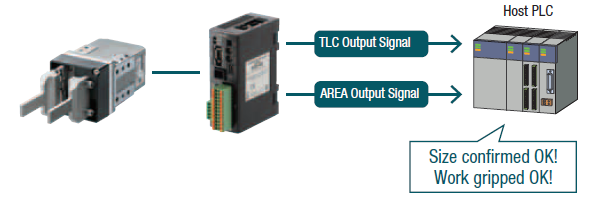

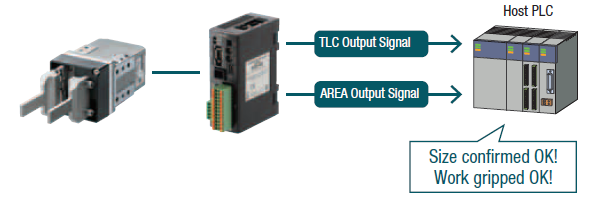

The EH Series grippers also have built-in mechanical absolute encoders. These help detect the presence of a load and confirm its dimensions. Additional outputs like TLC, MOVE, and AREA allow for real-time monitoring of the gripping process.

- TLC Output: Activates when a set grip force is reached.

- MOVE Output: Indicates when the motor is moving.

- AREA Output: Signals when the motor is within a specific position range.

By combining push motion, speed control, and encoder feedback, you can achieve precise and reliable gripping of delicate parts. Whether through wiring or network commands, the EH Series provides flexibility and efficiency in automation setups.

Conclusion

Using the EH Series gripper system with push motion, variable speeds, and advanced encoder technology ensures safe and efficient handling of sensitive loads. This makes it ideal for applications where precision and care are essential.

Explore more about the AlphaStep family of products and how they can simplify your automation setup. With shared drivers and easy parameter transfer, integrating new axes becomes straightforward.

Subscribe to stay updated with the latest insights and tips on automation and robotics.

Weichai Engine Spare Parts

Weichai Steyr WD615, 6105, Deutz 226B, Original quality and best price for Wheel loader spare parts.

Weichai Engine Spare Parts,Motor Grader Egr Cooler,Air Cleaner Engine Parts,Coolant Water Engine Spare Parts

Model meaning of Weichai Deutz TD226B-6D

T stands for supercharging; D stands for diesel engine; 2 stands for water cooling; 26 stands for diesel engine serial number; B stands for wet Cylinder liner; 6 stands for diesel engine with 6 cylinders, D stands for diesel engine for power generation.

Bus:

Landking WP12 National III/National IV, WP10/WP6/WP4 National III passenger car diesel engine

WD615 series passenger car diesel engine

226B series passenger car diesel engine

WT615/226B series passenger car gas engine

Truck's:

Landking WP12 Country III/ Country IV, WP10/WP6/WP4 Country III truck diesel engine

Weichai WD12 series truck diesel engine

WD615 series truck diesel engine

226B series truck diesel engine

Power generation:

Weichai Deutz 226B series diesel engine for power generation

Weichai WD615/WD618 series diesel engines for power generation (WD stands for Weichai Power, also known as Weidong, 6 is 6 for 6 cylinders, and 15 for single cylinder displacement is 1.5L)

Weichai X6160/R6160 series diesel engine for power generation

Weichai 170 series diesel engine for power generation

Weichai CW200 series diesel engine for power generation

For boats:

Weichai WP12C series marine diesel engine

Weichai Deutz 226B series marine diesel engine

Weichai WD615 series marine diesel engine

Weichai WD618 series marine diesel engine

Weichai R6160 series marine diesel engine

Weichai X170ZC series marine diesel engine (including 6170, 8170)

Weichai CW200ZC series marine diesel engine

Agricultural:

Weichai Deutz 226B Series Agricultural Diesel Engine

Weichai Engine Spare Parts,Motor Grader Egr Cooler,Air Cleaner Engine Parts,Coolant Water Engine Spare Parts

Jinan Union Construction Machinery Co., Ltd. , https://www.tfloaderparts.com