A gripper is a crucial component in automation systems, typically mounted at the end of a robotic arm or on a Cartesian robot. It's designed to pick up and move parts from one location to another. However, using a gripper properly involves more than just closing its jaws. In this post, we’ll explore how to grip delicate loads without causing damage.

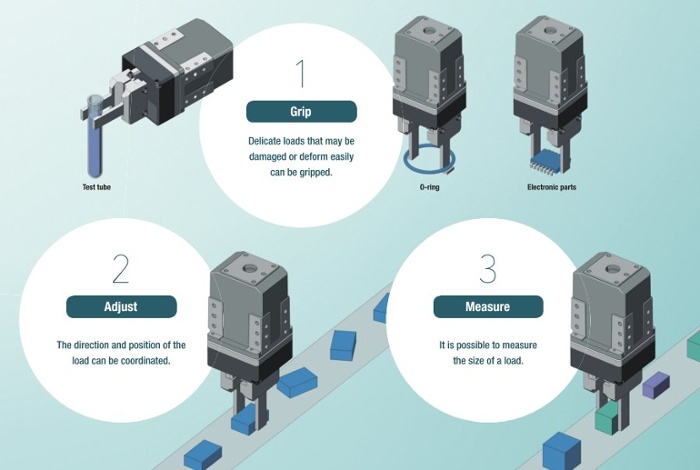

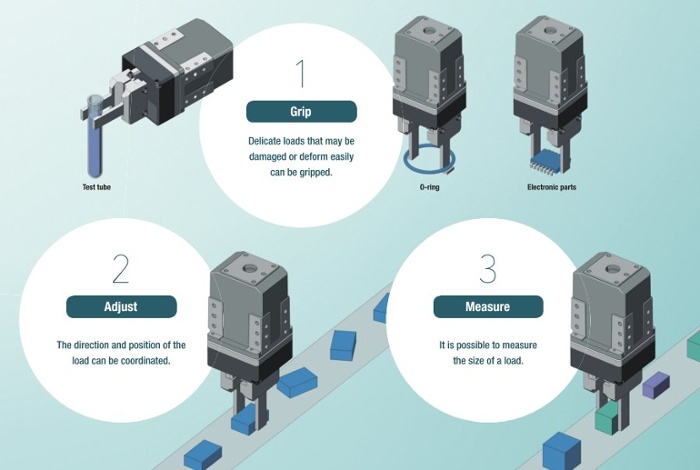

Imagine handling something as fragile as a test tube filled with virus samples. The challenge here isn't just about positioning but also about controlling the grip force and speed to avoid any damage. This principle applies to many types of sensitive loads.

| CHALLENGE |

Grip a delicate part without damaging it

|

Â

![Gripping a delicate load]()

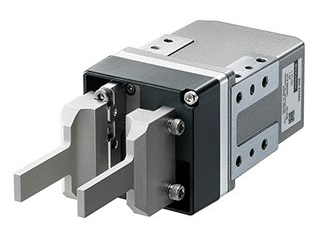

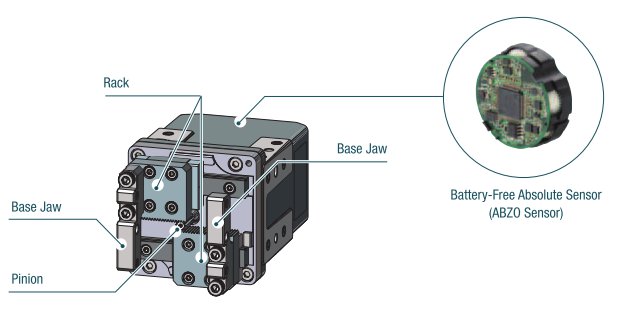

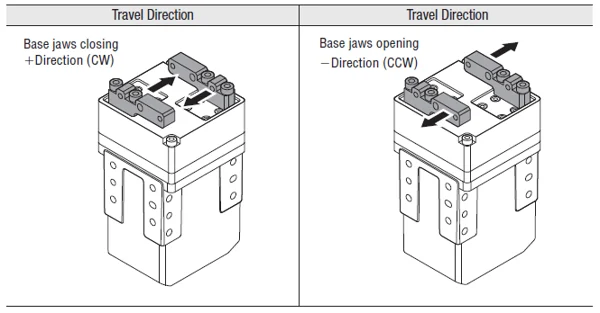

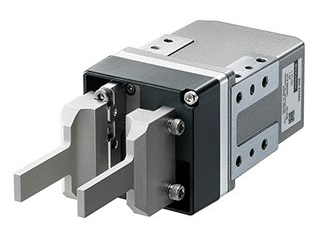

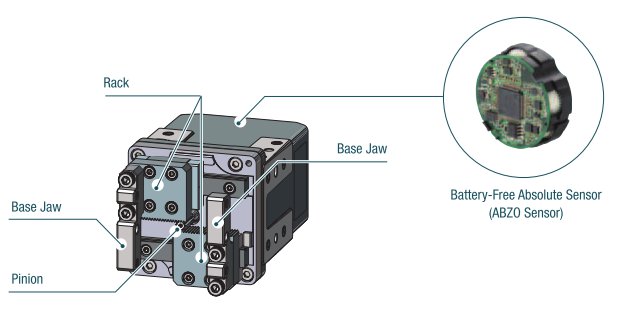

The EH Series gripper system offers an advanced solution for such applications. With its dual rack and pinion design, it ensures precise movement with a repetitive accuracy of ±0.02 mm. Its versatility allows different gripper arms to be attached, making it suitable for various load types.

There are several driver options available, including Pulse Input, Pulse Input + Stored Data (RS-485), and others. Each option provides different levels of control and flexibility depending on your needs.

- Pulse Input

- Pulse Input + Stored Data (RS-485)

- Stored Data (RS-485)

- EtherCAT (1-4 axes)

- EtherNet/IP (single axis)

- Other industrial communication protocols available with network converters

|

For example, the Pulse Input + Stored Data (RS-485) driver allows remote monitoring and control through an RS-485 network. This makes it ideal for complex automation setups where real-time feedback is essential.

The EH Series also features a battery-free absolute Sensor (ABZO sensor), eliminating the need for external sensors and batteries. Combined with AlphaStep hybrid control technology, it ensures reliable operation and prevents missed steps.

One key feature of the EH Series is its ability to store up to 256 motion profiles, allowing for precise control over grip force and speed. These profiles can be programmed using the MEXE02 software and executed via BCD inputs.

|

What Is Push Motion?

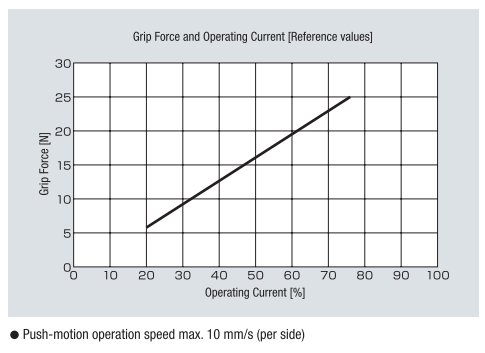

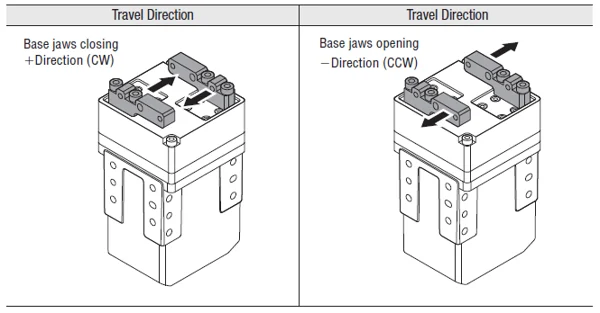

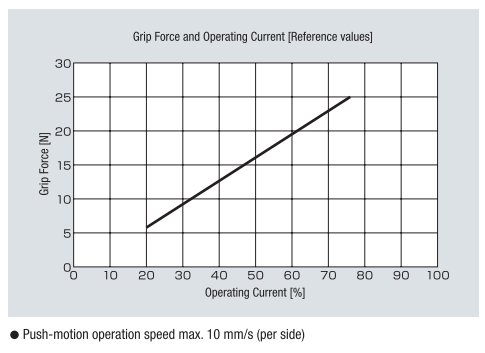

Push motion is a technique that limits the torque of a stepper motor by controlling its current. By adjusting the current in 1% increments, you can precisely control the grip force. This is especially important when dealing with delicate items like test tubes.

|

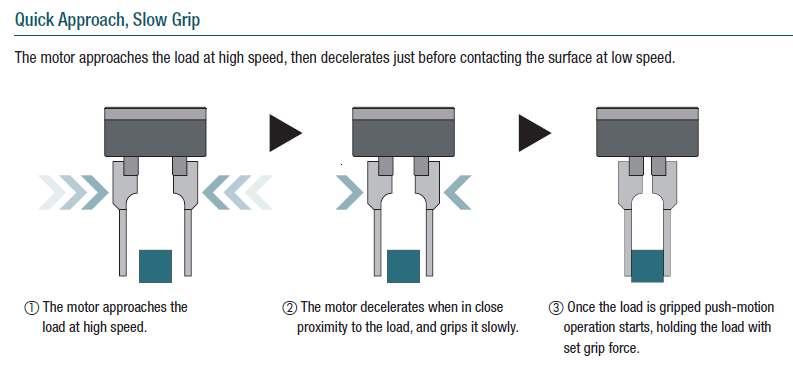

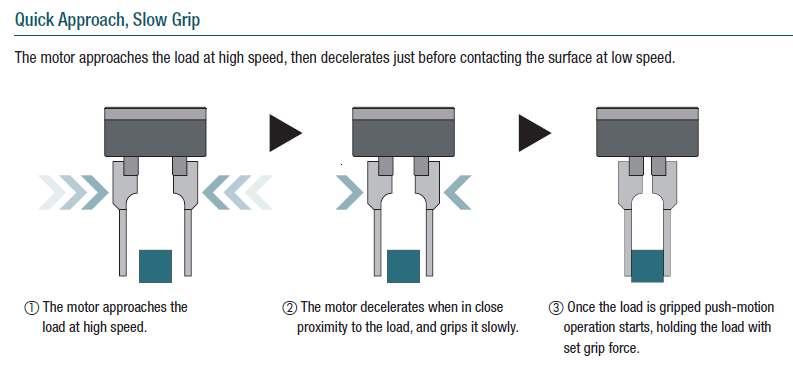

Using push motion with multiple speed settings helps minimize impact force and protect delicate parts. For instance, a gripper can approach a test tube at high speed, slow down when close, and then grip it gently. Once the desired grip force is achieved, the gripper holds it constant until the part is released.

| Key Point |

Use push motion with multiple speed settings to minimize impact force and impact

|

With the linked motion sequence function, you can create continuous motion profiles with varying push motion forces and speeds. This ensures smooth and controlled operations, which is vital for handling sensitive materials.

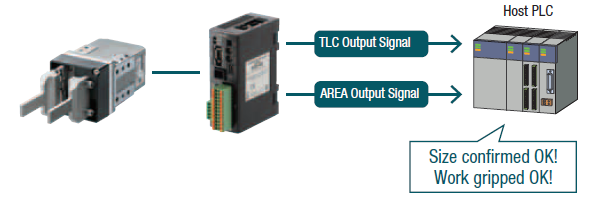

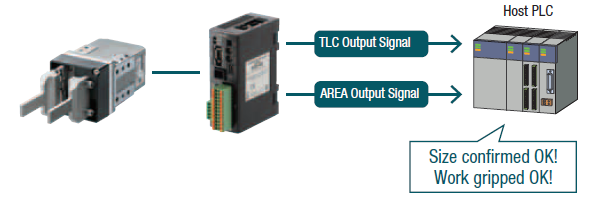

The built-in mechanical absolute encoder in the EH Series helps detect the load and confirm its dimensions. The stored data driver also provides useful outputs like TLC, MOVE, and AREA, which can be accessed physically or remotely.

- TLC Output: Activates when a set grip force is reached

- MOVE Output: Activates when the motor is moving

- AREA Output: Activates when the motor is within a set position range

By combining push motion, speed settings, and the driver’s outputs, you can ensure a reliable and efficient gripping process for delicate parts. Whether you're working with test tubes or other sensitive materials, the EH Series gripper system offers a flexible and robust solution.

Conclusion

The EH Series gripper system is an excellent choice for applications requiring precision and care. Its advanced features, such as push motion, speed control, and mechanical absolute encoders, make it ideal for handling delicate loads efficiently and safely.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fdb88bb6-1bf6-4f5d-a90e-f5d82f1c1eb5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fdb88bb6-1bf6-4f5d-a90e-f5d82f1c1eb5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fad37be8-6d75-4fd1-93df-2ea7037b188a', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fad37be8-6d75-4fd1-93df-2ea7037b188a', {"useNewLoader":"true","region":"na1"});

Simplify your setup and control by using products from the same AlphaStep family. All AlphaStep products with AZ Series mechanical encoder technology use the same dedicated drivers, making it easy to add and configure axes. Stored motion data and parameters can also be transferred between axes. To help shorten the learning curve, software training videos are available.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '59c67a88-c8f7-452d-8792-36ff47c50ace', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '59c67a88-c8f7-452d-8792-36ff47c50ace', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '39ae2306-a4c3-4ac6-ad3c-749ca7c0cb64', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '39ae2306-a4c3-4ac6-ad3c-749ca7c0cb64', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});

Thanks for reading! Don’t forget to subscribe if you want to stay updated on new posts.

Engine

An engine is a machine that can convert other forms of energy into mechanical energy, including internal combustion engines (reciprocating piston engines), external combustion engines (Sterling engines, steam engines, etc.), jet engines, electric motors, etc. For example, internal combustion engines usually convert chemical energy into mechanical energy. The engine applies both to the power generating unit and to the entire machine including the power unit

Alternator For Loader Engine,Loader Engine Parts Alternator,Wheel Loader Spare Parts,Loader Engine Parts Alternator

Jinan Union Construction Machinery Co., Ltd. , https://www.tfloaderparts.com

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fdb88bb6-1bf6-4f5d-a90e-f5d82f1c1eb5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fdb88bb6-1bf6-4f5d-a90e-f5d82f1c1eb5', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fad37be8-6d75-4fd1-93df-2ea7037b188a', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'fad37be8-6d75-4fd1-93df-2ea7037b188a', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '59c67a88-c8f7-452d-8792-36ff47c50ace', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '59c67a88-c8f7-452d-8792-36ff47c50ace', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '39ae2306-a4c3-4ac6-ad3c-749ca7c0cb64', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '39ae2306-a4c3-4ac6-ad3c-749ca7c0cb64', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});