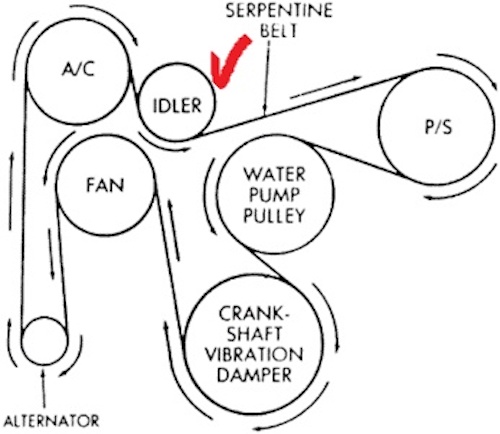

An idler pulley is a simple yet essential component in many vehicles, designed to maintain proper tension on the serpentine belt. Over time, this part can wear out and eventually fail, which is why regular maintenance is important. While replacement intervals can vary, most idler pulleys last between 50,000 and 100,000 miles. Often, they are replaced at the same time as the serpentine belt, making it a good idea to check both during routine service. Not all vehicles have an idler pulley, but for those that do, it plays a crucial role. The serpentine belt connects to the engine’s crankshaft and powers various components like the alternator, air conditioning compressor, and power steering pump. This belt moves around the front of the engine, and the idler pulley helps keep it tight, ensuring it maintains enough friction to operate these systems effectively. Think of the idler pulley as a helper that keeps the belt from slipping. On most cars, the tension is adjusted by sliding the pulley along a rail and securing it in place. In some cases, a spring mechanism applies the necessary pressure. Either way, the goal is to ensure the belt stays tight and functions properly. The main failure points of an idler pulley are usually its bearings or the tensioning spring. If you notice any unusual noises like squeaking, or if the pulley feels wobbly when turned, it might be time for a replacement. Regular inspections can help catch issues early and prevent more serious problems down the road. Image Copyright Una Smith To extend the life of your idler pulley, always make sure the serpentine belt is properly tensioned and replace it when needed. A worn belt can cause excessive strain on the pulley, leading to premature failure. Keeping everything in good condition helps your car run smoothly and reliably. Replacing an idler pulley varies depending on the vehicle, but it's generally a straightforward task. Labor costs can add up, especially if the belt needs to be removed first. However, with a bit of mechanical know-how, many people can tackle this job themselves. A professional mechanic can usually complete the repair in under 30 minutes, making it a relatively quick and affordable fix.

Cold drawn welded tubes size from 6mm to 329mm,Welded Drawn Over Mandrel(DOM Steel Tubing),cold finished or bright

annealed as customer requested,the tubes suitable for producing hydraulic fluid line pipes,precision bush,shock absorber

gas spring,hydraulic cylinders,precision shaft,jack cylinders and shaft,pneumatic cylinders etc.

Our products norm:

ASTM A513 type5,SAE J525,DIN2393,DIN EN10305-2,JIS G3445,JIS G3444

USA Steel Grade:DOM 1020,DOM1026,AISI4130,AISI4140

German Steel Grade:St37,St44,St45,St52

European:EN10305-2,E215,E235,E255,E275,E355,S235,S275,S355J2

Japan:STKM11A,STKM12A/B/C,STKM13A/B/C

Welded Tubes,Cold Drawn Welded Tubes,Welded Cold Drawn Tubes,Cold Drawn Welded Steel Tubes Ningbo Huijie Steel Pipe Manufacturing Co.,Ltd , https://www.hjbearingtube.comThe Idler Pulley's Role

Maintain Proper Tension

Replacing the Idler Pulley

Maximizing the Lifespan of Your Idler Pulley