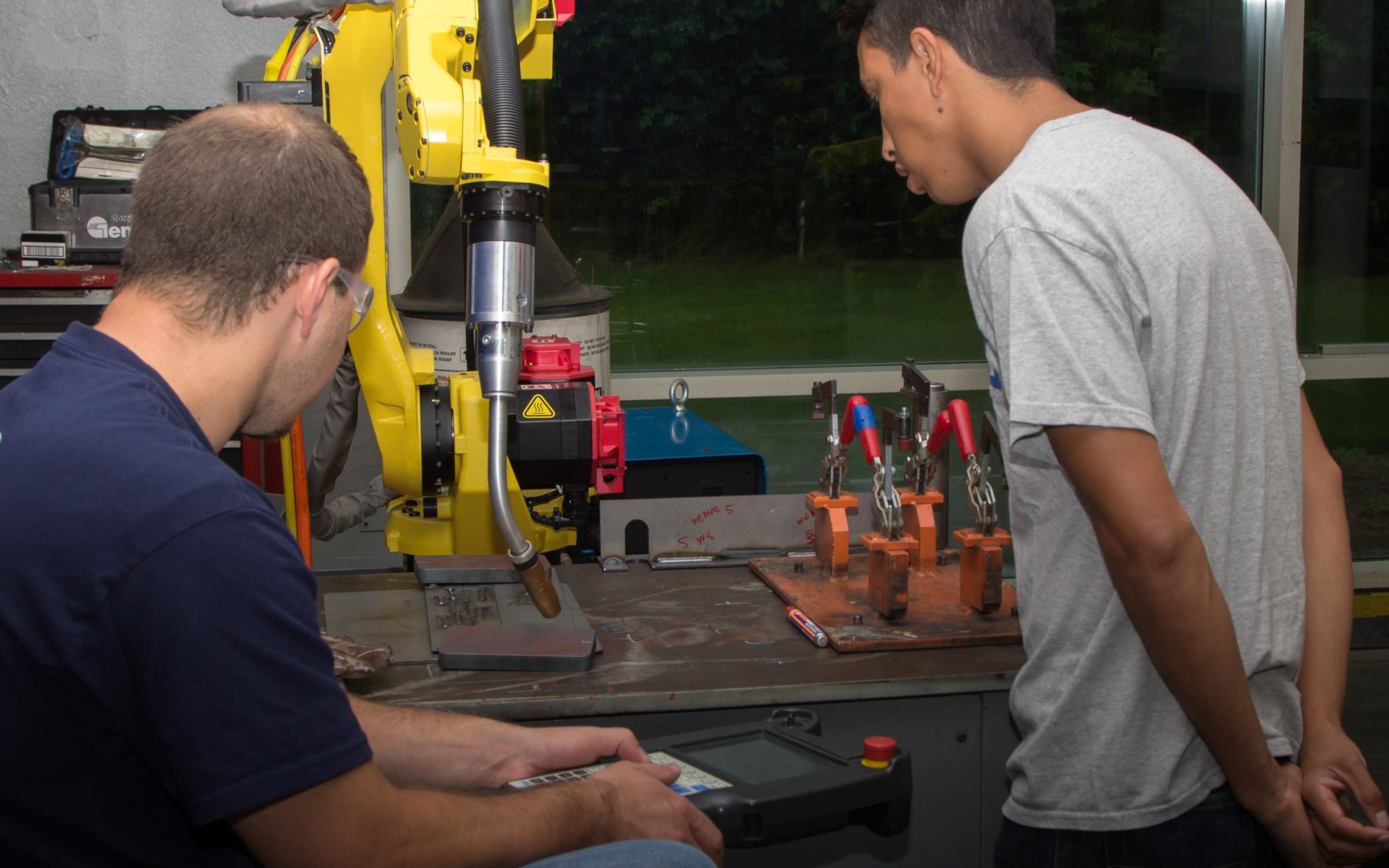

Introducing robotic automation into any facility necessitates well-trained operators who can ensure smooth operations. Proper robot operator training is not just beneficial—it’s essential for maintaining optimal productivity. As businesses adopt newer, more advanced robotic systems, it becomes increasingly vital for operators to stay updated on the latest technologies and programming methodologies. Fortunately, numerous robot training programs exist, and many robot integrators provide these services. Regardless of which program you opt for, the advantages of having skilled and knowledgeable operators cannot be overstated—they significantly enhance operational efficiency and profitability. One of the most significant benefits of robot training is enhanced productivity. When new robotic systems are introduced, thorough training reduces the learning curve and minimizes downtime due to inexperience. Additionally, safety is a core component of any training program. Operators who fully grasp how to operate robots safely contribute to minimizing accidents, thereby reducing downtime and preventing potential injuries. Moreover, robot training plays a crucial role in maximizing the return on investment (ROI) for capital expenditures. Well-trained operators are better equipped to handle complex tasks and optimize system performance, ultimately boosting output and profitability. By keeping robotic systems running efficiently, operators play a critical role in ensuring the long-term success of robotic cells within a facility. With so many robot training programs available, it’s important to select one that aligns with your specific needs. A quality training program should offer small class sizes with ample hands-on experience. Ideally, approximately 20% of the course should consist of lectures, while the remaining 80% should involve practical exercises with real robotic systems. This balance ensures that participants gain both theoretical knowledge and practical skills. Another critical factor is the trainer's expertise. The instructor should be an experienced professional with extensive knowledge of various robotic systems and programming techniques. Personalized instruction tailored to the unique requirements of each participant is essential for effective learning. Such trainers can address specific challenges faced by operators and provide actionable solutions. Robot training empowers operators to adapt to evolving technological advancements. By equipping operators with cutting-edge knowledge and skills, businesses can ensure sustained productivity and competitiveness in today’s dynamic industrial landscape. The right training program serves as a foundation for excellence, enabling operators to excel in their roles and drive organizational success. For further insights, explore Genesis Systems Group’s comprehensive robot training courses designed to meet the diverse needs of modern facilities. As industries continue to embrace automation, the demand for skilled robot operators grows exponentially. Training programs not only prepare operators for immediate challenges but also equip them with the foresight needed to anticipate future developments. By investing in high-quality training, companies position themselves at the forefront of innovation while fostering a culture of continuous improvement. In conclusion, proper robot operator training is indispensable for achieving operational excellence. It fosters a safer work environment, boosts productivity, and enhances ROI—all of which are critical for long-term success. Whether you’re implementing a new robotic system or seeking to refine existing processes, prioritizing operator training should always remain a top priority. Filter Mesh,Sintered Filter Element,Dutch Woven Filter Mesh,washable water filter mesh Hebei Yingkang Wire Mesh Product Co.Ltd , https://www.wiremesh-china.comThe Importance of Proper Robot Operator Training

The Key Advantages of Robot Operator Training

Key Features to Consider in a Robot Training Program

Here's how you might filter a substance using a mesh:

1. **Select the Appropriate Mesh**: Choose a mesh with a pore size that suits your needs. For instance, if you're filtering out dust particles, you would need a finer mesh. If you're separating larger solids from a liquid, a coarser mesh would suffice.

2. **Prepare Your Setup**: Depending on whether you're filtering a gas or a liquid, set up your system accordingly. This might involve positioning the mesh over a container to collect the filtered substance or within a machine designed for the specific process.

3. **Insert the Mesh**: Place the mesh into position. Ensure it is securely in place so that it doesn't move around during the filtering process, which could lead to uneven distribution of the substance being filtered.

4. **Feed the Substance**: Introduce the substance that needs to be filtered through the mesh. This could be done manually or via a pump or other mechanical means, depending on the volume and nature of the substance.

5. **Allow Filtration**: Allow the substance to pass through the mesh. The mesh will capture particles larger than its pore size, while allowing smaller particles and/or the fluid to pass through.

6. **Collect the Filtered Substance**: Once the desired amount has passed through, remove the mesh. If necessary, you may rinse the mesh to clean off any remaining particles.

7. **Dispose of Wastes**: Dispose of the captured particles according to your company’s waste management policies.

8. **Clean the Mesh**: Clean the mesh thoroughly after each use. This ensures that the mesh remains effective for future use.

Remember, the effectiveness of the filter mesh depends greatly on its proper selection and maintenance. Always ensure the mesh is compatible with the substance being filtered and that it is cleaned and maintained appropriately.

The Importance of Proper Robot Operator Training

# The Crucial Role of Comprehensive Robot Operator Training

A filter mesh is a type of material that allows for the separation of particles or fluids based on size. It is commonly used in various industrial processes, including air filtration, liquid filtration, and solid-liquid separation. The mesh can be made from different materials like metal, plastic, or fabric, and its pore size varies depending on its intended use.