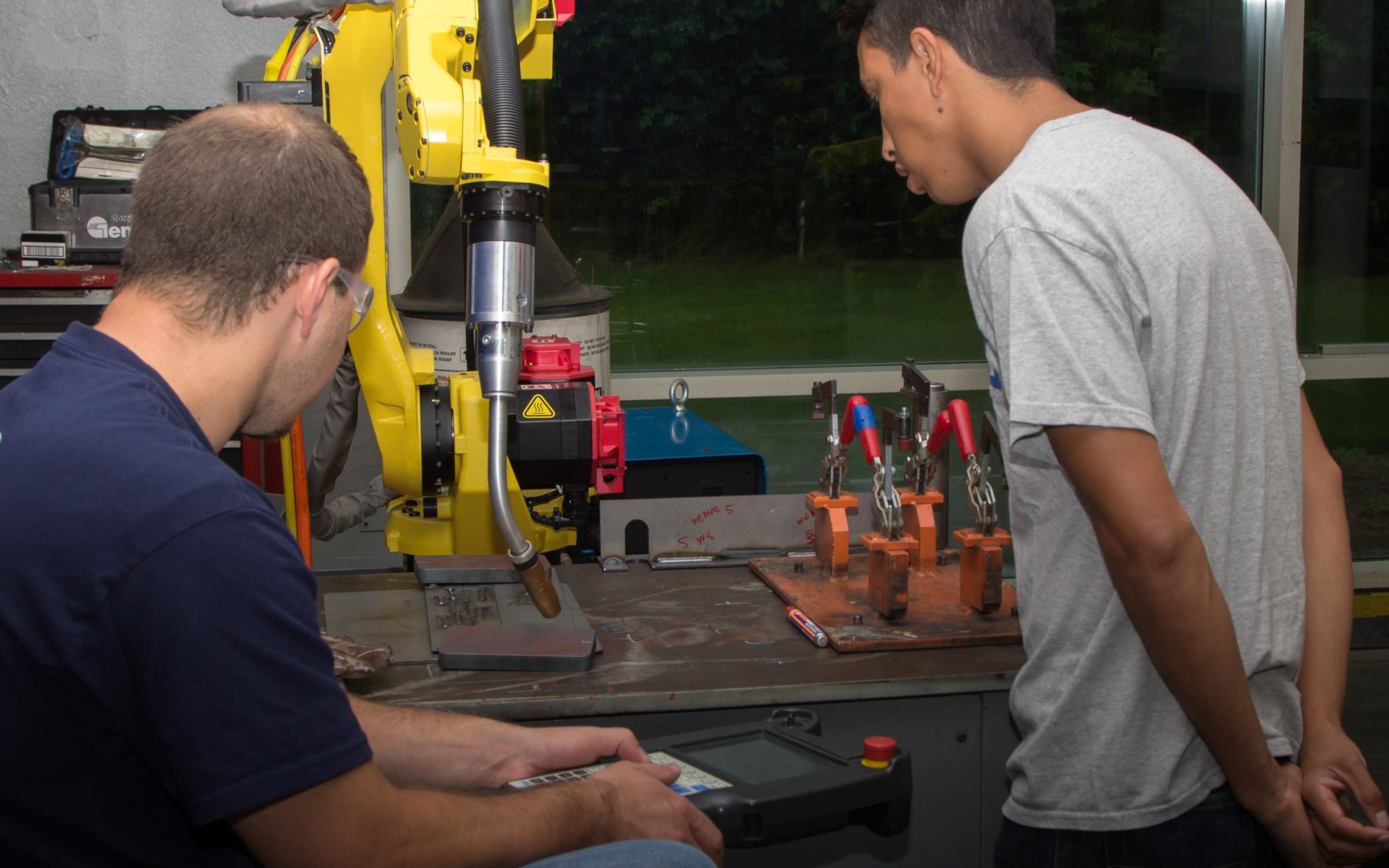

Introducing robotics into any operational setting inevitably demands skilled, well-trained operators to sustain optimal productivity. Robotic training is an indispensable component of ensuring long-term robotic efficiency—operators must consistently stay abreast of the latest technological advancements and programming methodologies. A variety of robot training programs exist, and your chosen robot integrator might even provide these services. Regardless of which program you select, the advantages of having informed operators will significantly enhance your company's profitability. One of the primary benefits of robot training lies in boosting productivity, particularly in the immediate aftermath of implementing new robotic systems. Training minimizes the learning curve and any associated downtime due to inexperience. Safety remains a central focus of training, and operators who fully grasp how to foster robot safety contribute to avoiding injuries and preventing workplace accidents that could lead to costly downtime. Training also plays a crucial role in maximizing the return on investment (ROI) for capital expenditures. Skilled robot operators can deliver greater value to their organizations by leveraging advanced skills. These operators are tasked with maintaining peak productivity in robotic systems and optimizing the uptime of robotic cells—comprehensive knowledge equips them to achieve these goals daily. With numerous robot training programs available, it's essential to identify specific features to ensure operators receive the education they require. First and foremost, you should seek out programs that offer small class sizes and emphasize hands-on training. Operators should actively engage with robotic workstations during their courses, ideally with a balance of approximately 20% lecture time and 80% practical experience. Another critical factor is the experience level of the instructor. The person leading the training program should be an industry expert with extensive knowledge of diverse robot systems and programming techniques, capable of tailoring the course content to meet the unique needs of participants. Robot training is vital for operators because they need to stay updated with evolving robotic technologies to consistently enhance productivity in robotic processes. The appropriate training program provides them with all the necessary tools to excel in their roles. To learn more, explore Genesis Systems Group's hands-on robot training courses. Investing in comprehensive operator training not only improves productivity but also fosters a safer work environment while maximizing equipment ROI. As industries continue to embrace automation, prioritizing operator education becomes increasingly important for long-term success. Remember, a well-trained workforce is a competitive advantage. By providing your team with access to high-quality training, you're empowering them to innovate, adapt, and thrive in today's rapidly changing industrial landscape. Whether you're just starting your journey into robotics or looking to refine existing practices, the right training program can make all the difference. Filtration Wire Cloth,Stainless Steel Filtration Mesh Screen,Copper Wire Mesh Cloth For Signal Shielding Hebei Yingkang Wire Mesh Product Co.Ltd , https://www.wiremesh-china.comThe Critical Role of Comprehensive Robot Operator Training

The Key Advantages of Robot Operator Training

Finding the Right Robot Training Program

The Importance of Proper Robot Operator Training

# The Critical Role of Comprehensive Robot Operator Training

Filtration wire cloth is a type of metal mesh used for various filtration applications. It's made by weaving or drawing wires into a mesh structure, which can then be used to filter out particles from liquids or gases.

Here are some key aspects of filtration wire cloth:

1. Materials: The wire used can be made from a variety of metals including stainless steel, brass, bronze, copper, and nickel. Each has its own characteristics in terms of corrosion resistance, strength, and conductivity.

2. Weaving Techniques: Filtration wire cloths are woven using different techniques like plain weave, twill weave, and reverse weave. These techniques affect the pore size and overall structure of the mesh.

3. Pore Size: The size of the openings (or pores) in the wire cloth determines its filtering capability. Smaller pore sizes are needed for finer filtration, while larger pore sizes are sufficient for coarser materials.

4. Applications: Filtration wire cloth is used in a wide range of industries including food processing, pharmaceuticals, chemical processing, and oil & gas. It can be used in filters for water purification, air filters, coffee filters, and more.

5. Quality Control: The quality of the wire cloth is important as it affects the efficiency of filtration. Factors like mesh count (number of openings per linear inch), wire diameter, and weave pattern all contribute to its performance.

6. Customization: Wire cloths can be customized to meet specific needs, such as custom dimensions, materials, and surface treatments (e.g., electroplating, anodizing).