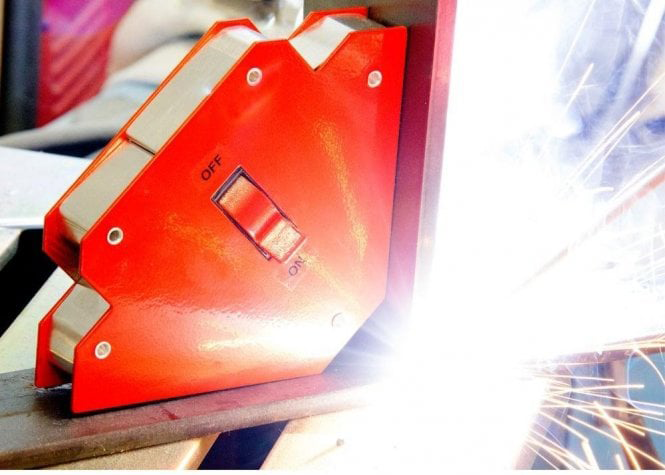

Welding is the process of joining two materials, typically metals, by applying heat, pressure, or both. This fusion results in a solidified joint once the materials cool. Ensuring that metal components remain stable during welding is critical, and this is where magnetic welding clamps play an indispensable role. Magnetic welding clamps are specialized tools designed to secure metal workpieces firmly during welding operations. These clamps utilize powerful magnets to hold pieces together, even when dealing with intricate shapes or difficult angles. Their ability to maintain stability makes them invaluable in various welding scenarios. Below, we delve into how these clamps function and explore their numerous advantages. At the heart of every magnetic welding clamp lies a ferrite magnet combined with a robust clamp mechanism. Ferrite magnets offer unmatched strength while remaining highly resistant to heat and boasting an economical manufacturing cost. The clamp itself serves to stabilize the workpiece, while the magnet ensures it remains affixed securely throughout the welding operation. By generating a potent magnetic field, these clamps effectively immobilize the workpiece, allowing welders to concentrate fully on executing precise welds without worrying about unintended movement. Some models feature a mechanical switch, enabling users to deactivate the magnetic field temporarily. This feature allows for unrestricted positioning before reactivating the clamp to lock the piece in place. One notable advantage of incorporating a switching system is enhanced cleanliness. When deactivated, metal shavings or debris can be effortlessly removed from the surface of the magnet, ensuring optimal performance each time it’s used. Unwavering Stability A primary advantage of magnetic welding clamps lies in their unparalleled capability to keep metal components steady during welding tasks. This is particularly beneficial when handling complex geometries or awkward configurations where conventional clamping methods often fall short. User-Friendly Design Magnetic welding clamps are remarkably straightforward to operate. They attach seamlessly to workpieces and adjust effortlessly according to project requirements, making them suitable for diverse welding applications. No Surface Damage Unlike traditional clamps, magnetic welding clamps cause zero harm or marking to the workpiece since they exert no physical pressure on the material. Versatility at Its Best In terms of adaptability, magnetic welding clamps outshine standard alternatives. They function effectively across a broad spectrum of metallic surfaces, including curves and irregular forms, and support multiple welding techniques like MIG, TIG, and Stick welding. While magnetic welding clamps are generally safe to use, there are several safety considerations every welder should keep in mind. The intense magnetic field generated by these clamps can attract stray ferrous items like nails, screws, or tools, potentially turning them into hazardous projectiles if dislodged during welding activities. Therefore, it's crucial to clear the workspace of any such objects before beginning your task. Personal protective gear such as gloves and goggles must always be worn during operations. Additionally, maintaining a clutter-free environment reduces risks associated with accidental contact between the magnetic field and nearby metallic objects. By adhering to these guidelines, welders can enjoy the convenience and efficiency provided by magnetic welding clamps while minimizing potential hazards. Barbell and dumbbell set fitness equipment,Hard pull male and female pole bell,incline bench press equipment kangerte , https://www.corertefit.com

Understanding the Mechanism of Magnetic Welding Clamps

Advantages of Using Magnetic Welding Clamps

Safety Tips When Using Magnetic Welding Clamps

Magnetic Welding Clamps: The Ideal Solution for Secure and Easy Welding