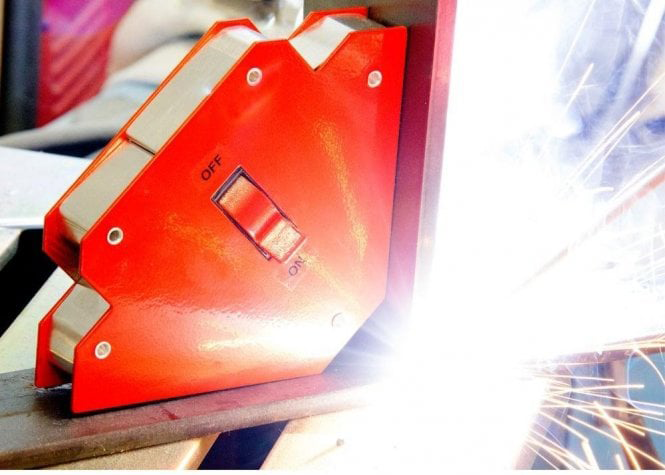

Welding is the process of joining two pieces together using heat, pressure, or a combination of both, creating a solid bond as the materials cool and stabilize. Securing metal workpieces in place during welding can be quite challenging, especially when dealing with intricate shapes or awkward angles. This is precisely where magnetic welding clamps come into play, providing an essential solution to keep your workpieces steady. Magnetic welding clamps are specially engineered tools that utilize powerful magnets to hold metal workpieces securely in place during welding. Whether you're working on complex designs or trying to manage tricky angles, these clamps offer unparalleled stability and precision. Below, we'll explore how magnetic welding clamps function and why they are becoming indispensable in modern welding operations. Our magnetic welding clamps consist of a ferrite magnet and a sturdy clamp mechanism. Ferrite magnets are renowned for their exceptional strength, high heat resistance, and cost-effectiveness. The clamp itself serves to secure the workpiece in position, while the magnet ensures it remains firmly attached to the metal surface. The ferrite magnet generates a robust magnetic field that keeps the workpiece stable throughout the welding process. This allows the welder to concentrate fully on the task at hand, eliminating concerns about the workpiece shifting or moving unexpectedly. In some models, the magnetic welding clamps feature a mechanical switch that enables users to turn the magnet off temporarily. This makes positioning the clamp much easier and more accurate since there is no residual magnetic force interfering with adjustments. Once properly aligned, the magnet can be switched back on to lock the clamp securely in place. Additionally, the switching mechanism offers practical advantages, such as simplifying cleaning. When the magnet is deactivated, any accumulated metal shavings or debris can be easily removed by wiping them away. Unmatched Stability One of the primary benefits of magnetic welding clamps lies in their unmatched ability to maintain a firm grip on metal workpieces during the entire welding operation. This advantage becomes particularly significant when handling complicated geometries or awkward positions, situations where conventional clamps often fall short. User-Friendly Design Magnetic welding clamps are incredibly user-friendly. Attaching them to a workpiece is straightforward, and they can be repositioned effortlessly whenever necessary. Their adaptability makes them suitable for a wide range of welding tasks. Damage-Free Operation Unlike traditional clamping methods, magnetic welding clamps leave no scratches or indentations on the workpiece because they apply no direct pressure. This ensures that the integrity of the material remains intact, preserving its aesthetic appeal and structural soundness. Extreme Versatility Magnetic welding clamps surpass conventional clamps in terms of versatility. They work effectively on various types of metal surfaces, including curved and irregular ones. Furthermore, they accommodate multiple welding techniques like MIG, TIG, and Stick welding, enhancing their utility across diverse projects. While magnetic welding clamps are generally safe to use, certain safety considerations must be observed to prevent accidents. The strong magnetic fields generated by these clamps can attract stray ferrous items, such as nails, screws, or tools. If these objects detach during welding, they pose a risk of becoming hazardous projectiles. Therefore, it's crucial to clear the workspace of all unnecessary metallic objects before beginning any welding activity. Welders should always wear proper protective gear, including gloves and safety glasses, to safeguard themselves from potential hazards. Adhering to these basic safety protocols will help ensure a safer working environment and protect both personnel and equipment. In conclusion, magnetic welding clamps represent a game-changing advancement in the field of welding technology. By offering superior stability, ease of use, and versatility, they address many challenges faced by welders today. As long as appropriate safety measures are followed, magnetic welding clamps promise to enhance productivity while minimizing risks associated with welding operations. Ball Sports,Snooker Pool Tables, kangerte , https://www.corertefit.com

Understanding How Magnetic Welding Clamps Operate

The Advantages of Using Magnetic Welding Clamps

Safety Guidelines for Magnetic Welding Clamps

Magnetic Welding Clamps: The Ideal Solution for Secure and Easy Welding