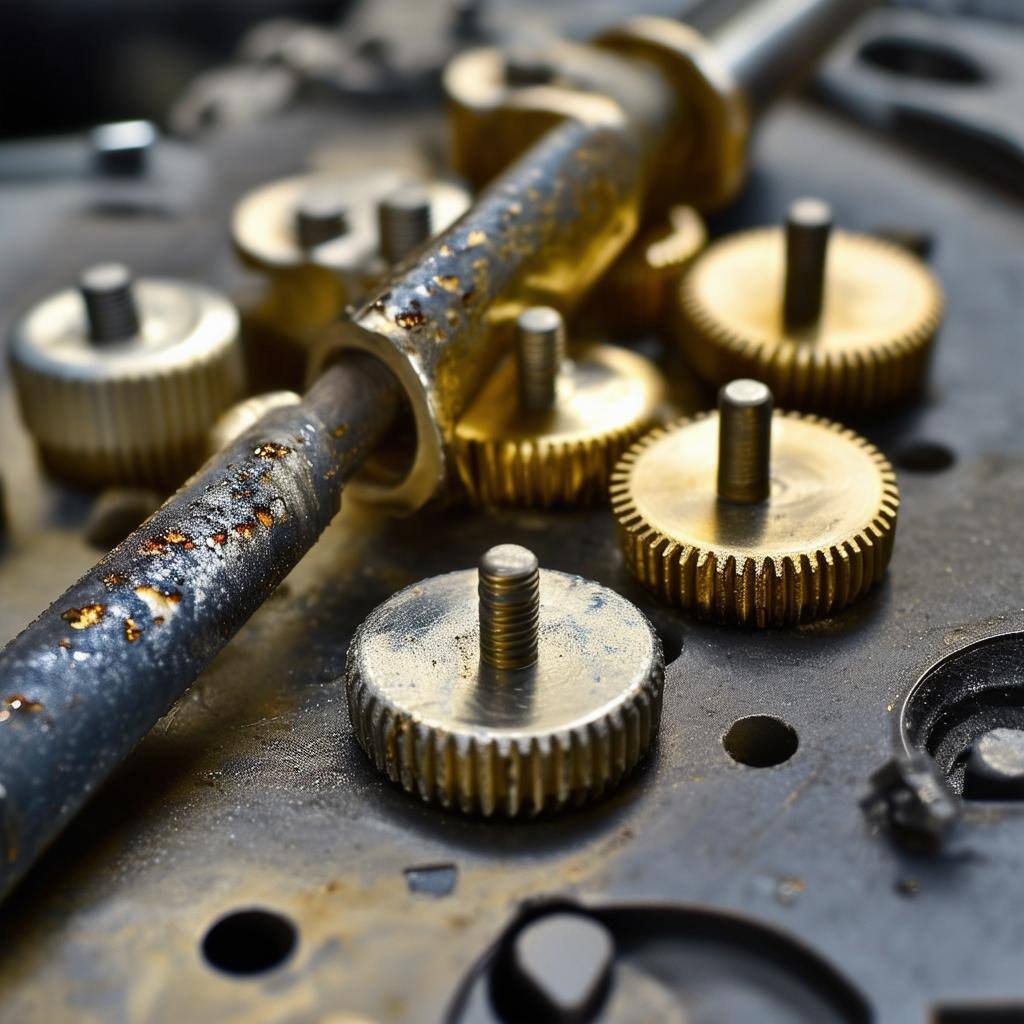

Standard pins are a staple in manufacturing across the globe, easily accessible thanks to their widespread availability and multiple suppliers. They’re cost-effective and reliable for many applications. However, there are situations where standard pins fall short, especially in demanding environments. Imagine using a pin in extreme conditions like high temperatures, corrosive substances, or intense physical stress—standard pins often fail to deliver the necessary resilience. In such cases, custom-engineered pins become essential. Industries like heavy machinery, industrial manufacturing, and military/aerospace frequently face harsh operating conditions. These environments can range from scorching heat to freezing cold, or from exposure to chemicals to constant vibration. Take, for instance, a piece of outdoor equipment where a standard pin might seem adequate but fails under corrosive weather. Here, a custom-plated pin from Bead Electronics would provide superior protection against corrosion while maintaining functionality and longevity. In sectors like automotive, aviation, and healthcare, the stakes are incredibly high. The performance of your product must be flawless to ensure safety and reliability. This means the pins used in these critical systems need to maintain consistent electrical connectivity, even under adverse conditions. Bead Electronics addresses this challenge by crafting custom contact pins with robust materials and advanced coatings. Our pins are engineered to handle the toughest scenarios without compromising on quality or performance. When you opt for customization, the possibilities are endless. Every aspect of pin design—from size and base metal to plating type—can be tailored to meet your exact requirements. Whether you're dealing with corrosive settings, physical stress, or vibration, Bead Electronics has the expertise to deliver the right solution. For applications prone to corrosion, consider noble metal plating or specialized surface treatments to enhance durability. Phosphor bronze pins outperform copper pins in terms of strength, making them ideal for high-stress environments. Switching from brass to steel alignment pins can significantly reduce the risk of cross shear. Bead Electronics provides reinforced mechanical designs to withstand shock and vibration, ensuring long-term reliability. We offer a range of unique pin geometries compatible with specialized connector housings, providing seamless integration. Choose the right metal for optimal conductivity. Explore our custom plating options to maximize efficiency based on your application. Seeking advice on customization? Browse through our hollow and solid wire options to discover all the possibilities available to you. At Bead Electronics, we focus exclusively on creating custom end-to-end, wire, and hollow pins. With our streamlined process, we can design and produce a custom pin to suit your needs within just two weeks, all while keeping costs manageable. Contact us today to kickstart your project! Let's build something extraordinary together. Jewelry Wire Rope,Jewelry Stainless Steel Wire Rope,Soft Stainless Steel Wire Rope,Wire Rope For Jewelry Taizhou City Yuansheng Stainless Steel Products Co., Ltd. , https://www.ss-wirerope.comChallenges in Harsh Environments

Ensuring Reliable Connections in Demanding Situations

Tailoring Solutions to Your Needs

Corrosion Protection:

Handling Physical Stress:

Avoiding Cross Shear:

Vibration Resistance:

Custom Connector Housings:

Enhanced Electrical Conductivity:

Partner with Bead for Tailored Pin Solutions

Durable Solutions: Custom Pins for Rugged and Harsh Environments