The COVID-19 pandemic has reshaped how we view and interact with the world. Last year was particularly challenging for businesses and the global economy, but as we move into 2021, many industries are showing signs of recovery. The solar energy sector is no exception. According to industry analysts, the Indian solar market is projected to grow at a compound annual growth rate (CAGR) of over 40% from 2020 to 2025. This growth is being driven by falling solar module costs and supportive government policies that allow 100% foreign direct investment (FDI) in the sector.

Let’s explore the **solar power trends** that will shape the future of the sector in 2021:

**Solar Panels Are Back in Demand**

Although demand for solar panels dipped last year due to economic slowdowns, the market is now showing signs of recovery. As businesses and industries reopen, there's a growing interest in renewable energy solutions. Solar manufacturers and installers can expect a steady increase in demand over the next few months. However, it may take some time before the market fully recovers to pre-pandemic levels.

**Booming Data Centers**

More companies are shifting toward cloud storage, realizing the cost savings and efficiency it offers. This trend is expected to continue, leading to a surge in demand for data centers. Many of these centers are committed to using 100% sustainable energy, which presents a great opportunity for solar manufacturers. As more data centers go green, the solar industry stands to benefit significantly.

**Artificial Intelligence (AI) and Digitalization**

The integration of AI and digital tools is becoming a key trend in the solar industry. Renewable energy systems require constant monitoring and maintenance, which can be complex. Drones and AI-powered software are helping streamline operations, reduce human effort, and improve efficiency. Machine learning is also playing a crucial role in optimizing performance and unlocking new potential for solar technology.

**Blockchain Technology**

Blockchain is gaining traction in the energy sector due to its transparency and security. It can be used to track and record energy transactions, making it ideal for the solar industry. By adopting blockchain, solar firms can develop innovative products that automate processes, cut down on transaction costs, and even generate new revenue streams.

**Solar-Powered Vehicles**

With the rise of electric vehicles (EVs), one of the biggest challenges is building enough charging infrastructure. Currently, there aren't enough EV charging stations, but this gap could become an opportunity for the solar industry. Solar technology can help power these stations, reducing reliance on fossil fuels and addressing environmental concerns. Vehicle manufacturers are increasingly looking for eco-friendly solutions, making solar-powered transportation a promising trend.

**Micro-Inverter Technology**

Micro-inverters offer a more efficient alternative to traditional string inverters in photovoltaic (PV) systems. They convert DC to AC at the panel level, providing better yield optimization and system flexibility. These devices also monitor each panel individually, maximizing energy output and improving overall system performance. As more consumers seek efficient and reliable solar solutions, micro-inverter technology is set to play a major role in the future of the industry.

These trends highlight the dynamic and evolving nature of the solar energy sector. With continued innovation and support, the industry is well-positioned to lead the global transition toward clean and sustainable energy.

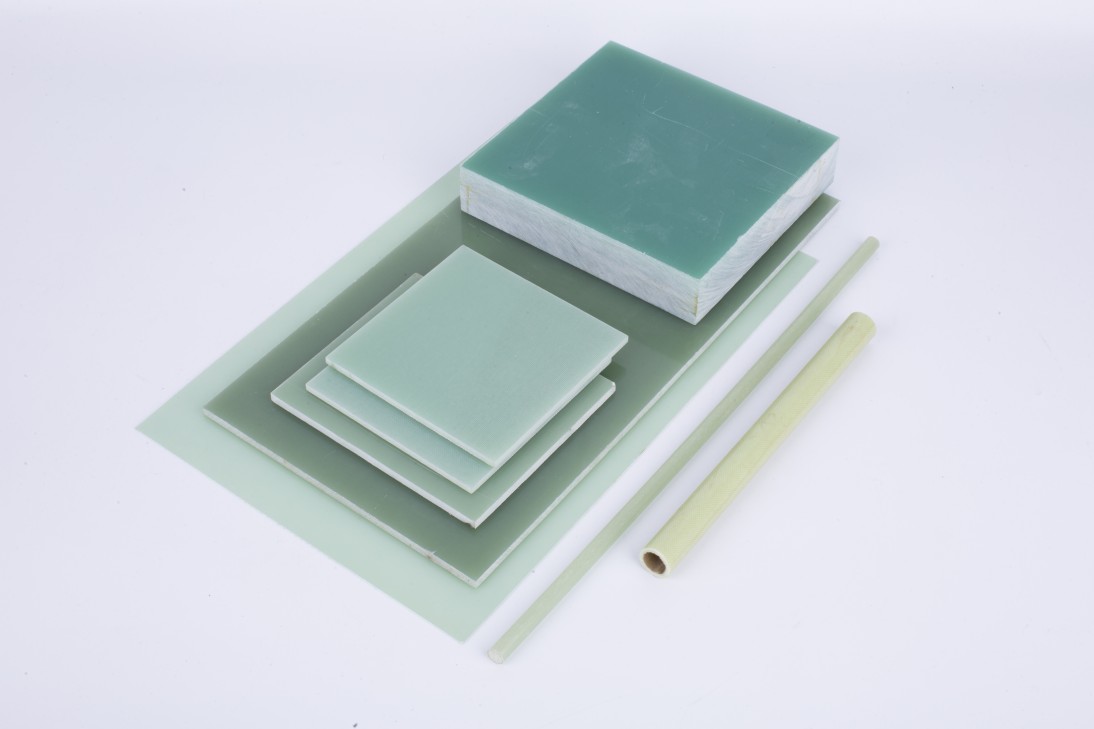

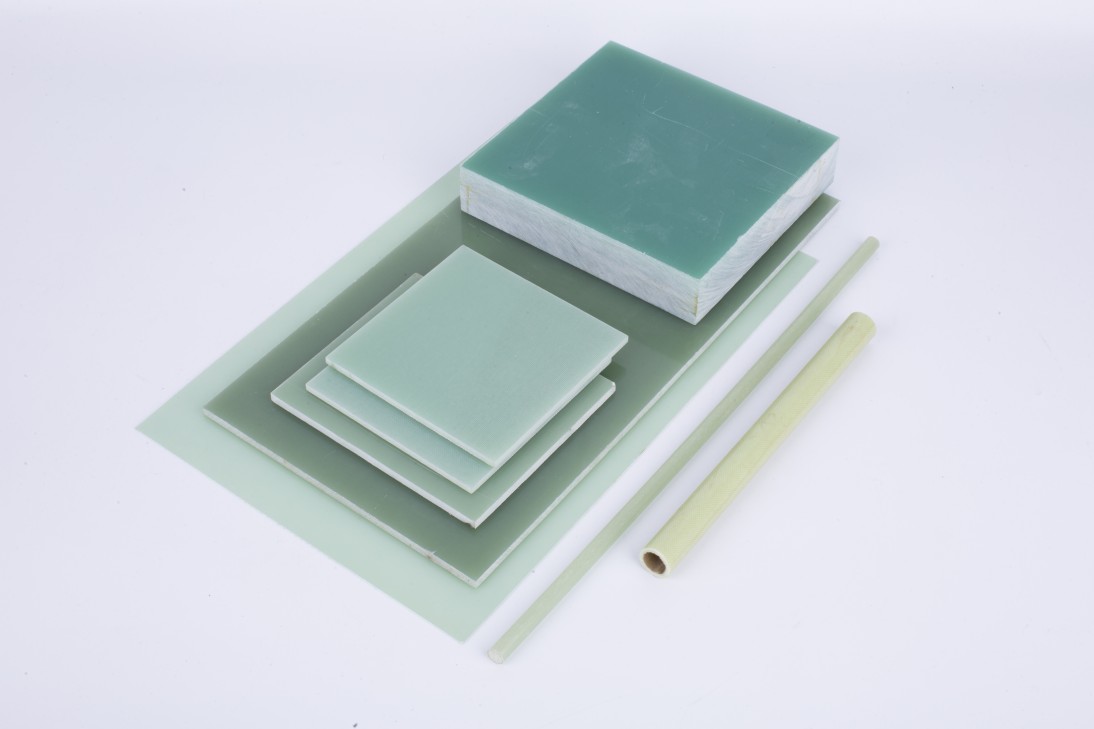

FR4 G10 Epoxy Fiber Glass Parts

HONY®FR4 is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiber cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for "flame retardant", and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968.

FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications.

Grade designations for glass epoxy laminates are: G-10 ,G-11, FR-4, FR-5 and FR-6. Of these, FR-4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4's self-extinguishing flammability characteristics. Hence, FR-4 has replaced G-10 in most applications.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates. Some applications where thermal destruction of the material is a desirable trait will still use G-10 non flame resistant.

G10 FR4 glass epoxy laminate Grade: G10/G11 Fiber Reinforced Composite

Colour: Sheets are supplied in green

Thickness: 0.80mm to 35mm

Subcategory: Epoxy; Filled/Reinforced Thermoset; Polymer; Thermoset

G10 FR4 glass epoxy laminate Description:

Fr4 G10 Glass Epoxy Cutting Board is specified for its extremely high strength and high dimensional stability over temperature. G-11 is used for terminal boards, high humidity applications, electrical and electronic test equipment and electric rotor insulation. G-11 is difficult to cut or machine and may require special equipment.

G-10 is slightly Stronger while G-11 is a better insulator and can withstand higher temperature G-11 and similar fibreglass reinforced thermosets are sometimes known as Garolite.

HONY Plastic is an industry leader in FR4 and G10 machining. We are able to maintain tolerances, create features and produce parts that even the material manufacturers deem unobtainable. By using high speed spindles capable of turning at 30,000 RPM, tightly controlled work envelopes and cutting edge work holding systems, HONY Plastic can machine components from the most simple part to the most intricate part on any of the 35 machines in our facility.

27" x 15" x 13" Work Envelope

Tolerances to +/- .00025" (0.006 mm)

Hole Diameters to 0.003" (0.076 mm)

Fiber Glass PCB board,Fr4 G10 washer spacer glasket,G10 FR4 glass epoxy laminate,FR4,G10,FR4 G10 Insulation Gasket Epoxy Fiber Glass,Wave soldering jig SMT jig FR4

Hony Engineering Plastics Limited , https://www.honyplastic.com