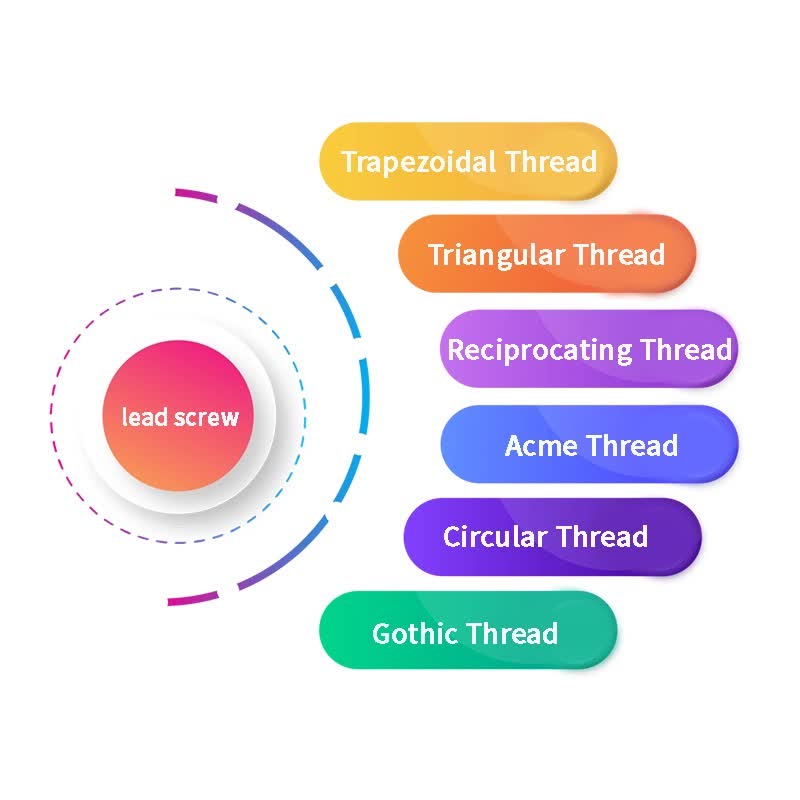

Lead Screws,Precision Lead Screws,Industrial Lead Screws, leadscrews, trapezoidal screws Suzhou Industrial Park Hojama Technology Co., Ltd , https://www.hojama-tech.com

---

**Red Copper Solid Rivet, Flat Head Copper Rivet M2, M2.5, M3**

**Product Description:**

Product Name

Red Copper Solid Rivet, Flat Head Copper Rivet M2, M2.5, M3

Material

Stainless Steel: SS201, SS303, SS304, SS316, SS410, SS420

Carbon Steel: 4.8, 6.8, 8.8, 10.9, 12.9

Titanium: GR1-GR5

Aluminum, Brass, etc.

Size

M2-M12 or as per your request

Head Type

Flat, JIS Pan, Oval, Round, Binding, I.HD, Brazier, PF.HD, Button, Fillister, ANSI.Pan, Pan Washer, Indented Hex, etc.

Standard

ISO, GB, DIN, JIS, ANSI, BSW, ASME

Certificate

ISO9001:2008, SGS Testing Report & RoHS

Screw Drivers

Phillips, Slotted, Truss, Square, Crossed, Y-type, T-type, Torx, PZ drives, Hex socket, etc.

Finishing

Zn-Plated, Ni-Plated, Tin-Plated, Radiant Plated, Passivated, Brass Plated, Cd-Plated, Phosphate Anodize, Cr-Plated, Black Oxide, etc.

Heat Treatment

Tempering, Hardening, Spheroidizing, Stress Relieving, etc.

Package

General Export Packaging or as per customer’s requirement

Delivery Time

Approximately 7–15 days after all details are confirmed. Fast delivery available for urgent orders.

Customer Service

Replacement at our cost for rejected products if the part does not match the PO drawings.

2. The four basic transmission modes of lead screw-nut pairs are as follows:​

Red Coppr Solid Rivet, Flat Head Copper Rivet M2 M2.5 M3

**Product Specifications:**

---

**About Shenzhen Conghui Precision Hardware Co., Ltd.**

Shenzhen Conghui Precision Hardware Co., Ltd. is a professional manufacturer with over 9 years of experience in producing high-quality industrial fasteners and precision parts. We specialize in screws, nuts, bolts, washers, rivets, anchors, and CNC components, strictly adhering to international standards such as GB, ISO, DIN, JIS, AISI, NFE, and BSW.

Our products are widely used in industries like machinery assembly, electronics, construction, and furniture manufacturing. We supply to markets across North America, Southeast Asia, and Europe, ensuring consistent quality and reliability.

We welcome both standard and custom orders, and we offer free samples upon request (shipping costs apply). Our goal is to provide excellent service, competitive pricing, and long-term partnerships with our clients.

---

**FAQs:**

1. **Q: Are you a trading company or a manufacturer?**

A: We are an industry and trade company, combining production and sales.

2. **Q: What is your product range?**

A: Our product line includes screws, nuts, bolts, washers, rivets, anchors, and CNC parts. We also accept non-standard designs.

3. **Q: Why should I choose you? What are your advantages?**

A: With 9 years of experience in fastener manufacturing, we provide comprehensive solutions from design to after-sales support. Customer satisfaction is our top priority.

4. **Q: In which industries are your products used?**

A: Our products are widely used in machine assembly, electronics, construction, and furniture manufacturing.

---

**Customer Service Highlights:**

- No questions asked refund within 3 days

- Professional and experienced team

- Short lead time

- International standards compliance

- OEM/ODM/customized services available

- Small quantity orders accepted

- Designed according to customer requirements

- Packaged and delivered as per customer instructions

If you have any further questions or need assistance, feel free to contact us anytime!

Hojama Cost-effective Lead Screws

1. Structural Characteristics of Lead Screw Pairs:​

1) Simple and compact structure, easy to process​

Composed of matching screw shaft and nut, their simple design enables compact sizing for space-constrained systems. Mature thread processing techniques reduce production difficulty and costs, facilitating mass application.​

2) Large reduction ratio (self-locking), smooth movement​

They provide significant speed reduction, with small screw shaft rotation translating to large nut displacement. Friction-induced self-locking secures the position when the driving force is removed, while operation remains stable with minimal vibration.​

3) Convenient to ensure and improve transmission accuracy​

Precision of thread profile, pitch, and alignment—controllable via mature manufacturing and post-processing like grinding—ensures high initial accuracy and room for enhancement, suiting precision machinery.​

4) Relatively large frictional resistance and low transmission efficiency​

Sliding friction between threads increases resistance, demanding greater driving force and resulting in lower efficiency compared to rolling friction-based mechanisms like ball screws, limiting high-speed/high-power use.​

5) Exist lateral clearance, with reverse idle stroke​

Radial gaps from manufacturing tolerances cause reverse idle stroke—driving parts must move a distance before reversing driven parts—impacting positioning accuracy in frequent-reversal applications.​

6) Micro and low-speed feeding has a crawling phenomenon​

Static/dynamic friction and system elasticity lead to uneven, jerky motion at micro/low speeds, hindering micro-positioning and precision machining quality.​

1) The screw shaft rotates while the nut moves axially​

Motor-driven screw rotation converts to axial nut movement, a common setup in linear actuators for displacement needs.​

2) The screw shaft rotates and moves axially while the nut remains stationary​

Screw combines rotation and axial movement (via dual-force driving mechanisms) with a fixed nut, useful in tools requiring rotational cutting and axial feeding.​

3) The screw shaft moves axially while the nut rotates​

Axial screw movement passively drives nut rotation, applied in systems converting linear motion to rotation, such as certain gearboxes.​

4) The screw shaft remains stationary while the nut rotates and moves axially​

Fixed screw guides rotating, axially moving nuts (driven externally). Nut displacement depends on rotation speed and thread pitch, suiting lifting devices or sliding platforms.